Forschungsinteressen

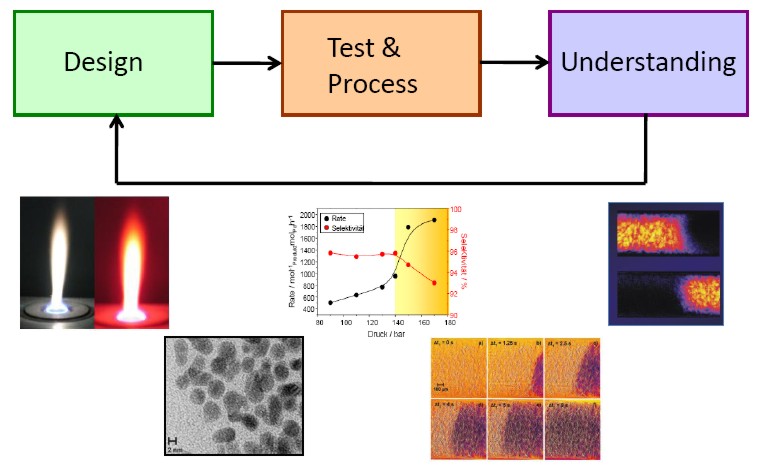

Unsere Forschung konzentriert sich auf die Entwicklung neuer Katalysatoren zur Umsetzung von Biomasse, zur Herstellung von Feinchemikalien sowie zur Emissionskontrolle. Mehr als 60% aller chemischen Prozesse basieren auf katalytischen Prozessen, wobei heterogene Katalysatoren momentan als auch zukünftig die Hauptrolle übernehmen, ebenso beim Wechsel von fossilen auf erneuerbare Rohstoffe. Daher sind drei Forschungspunkte von großer Bedeutung.

- Design: Synthese neuer Nanomaterialien.

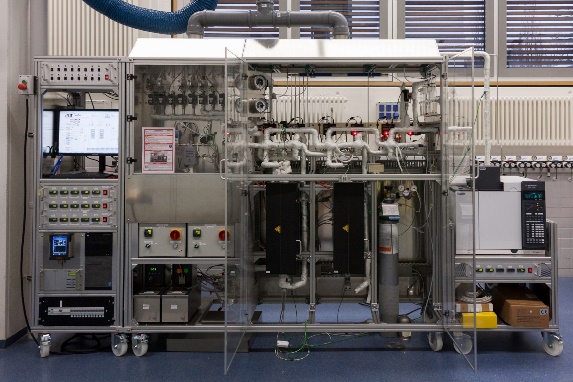

- Test & Process: Efffizienzorientierte Katalystortests.

- Understanding: Fundamentales Verständnis durch Verwendung Physikochemischer Analyse und in situ Spektrospkopie.

Ein kombinierter Ansatz wird angewandt, um katalytische Prozesse durch rationales Katalysatordesign zu verbessern.

Wir suchen nach motivierten Studierenden für Bachelor- und Masterarbeiten! Ein breites Wissensgebiet im Bereich der Katalyse, welches durch die Arbeit an einem unserer Projekte erworben werden kann, kommt dem Studierenden in der zukünftigen Karriere, sei es in der Industrie oder in der akademischen Laufbahn, zu gute. Unten können Sie Zusammenfassungen zu möglichen Bachelor-, Vertiefer- und Masterarbeiten finden oder schreiben Sie uns direkt an!

Themen:

- Nanomaterialien: Neue Präparationstechniken und Hochdurchsatz-Tests

- Environmental Catalysis

- Energierelevante Katalyse

- Biomass Conversion

- Selektive Oxidationsreaktionen

- In situ / operando Charakterisierung von heterogenen Katalysatoren

Präparation von Katalysatoren und Nanomaterialien

Nanomaterialien: Neue Präparationstechniken und Hochdurchsatz-Tests

Neuartige Präparationsmethoden für neue Nanomaterialien, effiziente katalytische Tests und korrekte Katalysatorcharakterisierung sind die Basis für das Design neuer Katalysatoren. So werden gegenwärtig beispielsweise Flammensprühpyrolyse, Präparationen unter Kontrolle der Partikelgröße oder hydrothermale Synthesen verwendet.

Betrachtete Reaktionen

Environmental Catalysis

Umweltverschmutzungen sind bereits seit Jahren globale Angelegenheiten, mit immer strengeren Auflagen. Insbesondere die Luftverschmutzung durch emittiertes NOx, CO, CO2, CH4, flüchtige organische Substanzen und Rußpartikel wird als massives Problem unserer Gesellschaft angesehen, mit schädlichen Auswirkungen für Gesundheit und Umwelt. Zusätzlich zur direkten Verringerung von Emissionen durch sparsamere Motoren, ist die katalytische Kontrolle von Emissionen eine der vielversprechendsten Ansätze. Diese Strategie erlaubt es die Emissionen sowohl von mobilen als auch stationären Emissionsquellen, wie Industrie, Transport und Haushal t, zu behandeln.

t, zu behandeln.

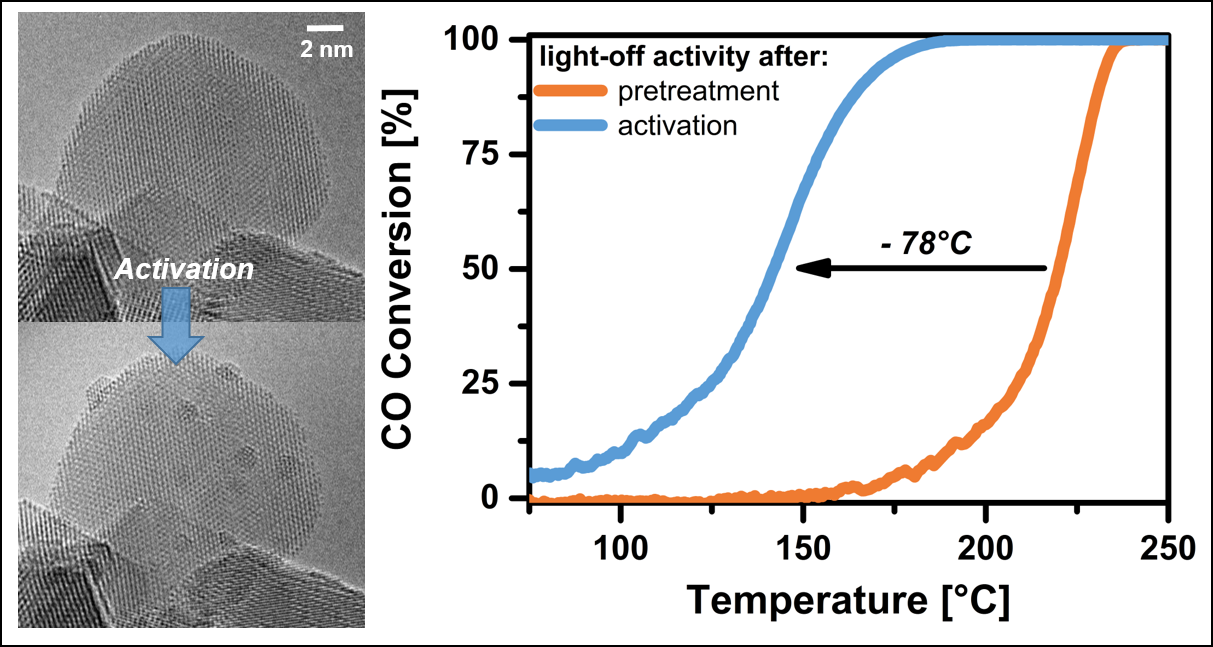

Um strengere Regulierungen der Emissionen zu erfüllen, müssen neue und verbesserte Generationen von Katalysatoren für die Emissionskontrolle entwickelt werden. Hierbei führt unsere Gruppe zahlreiche Studien über verschiedene Katalysatorsysteme durch, welche in der Nachbehandlung und Reduktion von Emissionen bei Diesel-, Benzin- und Erdgasmotoren sowie im Haushalt eingesetzt werden. Wir fokussieren uns dabei auf die Entwicklung eines fundamentalen Verständnisses von Struktur und Mechanismus, mit dem Ziel neue Katalysatorsysteme mit verbesserter Effizienz und Stabilität/Langlebigkeit zu entwickeln. Zum Beispiel waren wir in der Lage die katalytische Aktivität eines Pt-CeO2-basierten Systems durch Änderung der Partikelgröße der Edelmetalle, direkt signifikant zu verbessern. In Kooperation mit unseren Partnern in der Industrie, konnten wir beobachten, dass kurze reduzierende Pulse zu einem leichten Anstieg der Pt-Partikel bei milden Temperaturen führt, was einen enormen Effekt auf die katalytische Aktivität hat.

Mehr Informationen finden Sie auf der Internetseite unserer Emission Control Gruppe oder in unserem Emissionskontrollzentrum, welches in Kooperation mit Prof. Olaf Deutschmann geführt wird.

Mögliche Bachelor- oder Masterarbeit: Thema 1

Publikationen:

A. Gremminger, P. Lott, M. Merts, M. Casapu, J. -D. Grunwaldt, O. Deutschmann, Appl. Catal. B 2017, 218, 833.

Energierelevante Katalyse

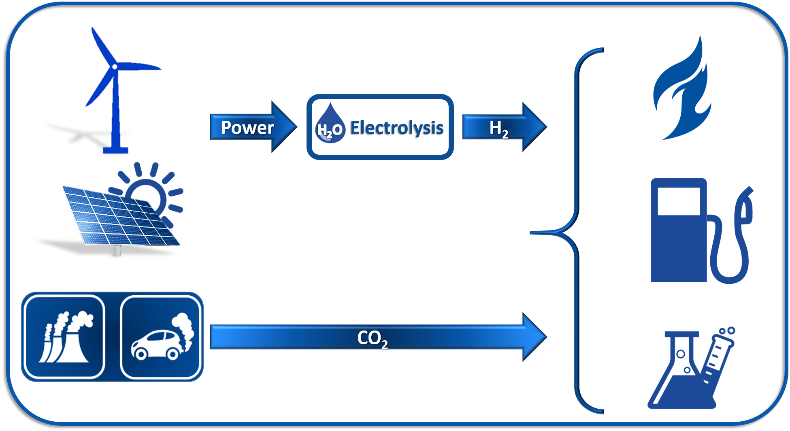

Der Klimawandel und der globale Energiebedarf haben zu verstärkten Bemühungen um eine effiziente Speicherung erneuerbarer Energien mit dem Ziel eines CO2-neutralen Ansatzes geführt. Eng damit verbunden ist die Herstellung von grünem Wasserstoff und Synthesegas (CO/H2), thermochemisch oder elektrochemisch. Unser Beitrag in diese Richtung ist state-of-the-art Forschung zu Katalysatorentwicklung, Prozessoptimierung und grundlegendem Verständnis.

Power to You via Power2X – Synthese von Energiespeichern von CO und CO2

Fortschritte bei der Erzeugung erneuerbarer Wind- und Solarenergie machen diese nachhaltigen Energieformen zu einer praktikablen langfristigen Option, um den steigenden Energiebedarf unserer Gesellschaft zu decken. Es besteht jedoch ein erhebliches Ungleichgewicht zwischen der Stromerzeugung und ihrer Nutzungskapazität. Um diese Probleme zu umgehen, müssen effiziente Energiespeicherlösungen entwickelt werden. Ein Beispiel ist die Power-to-X-Strategie, deren Kern die Umwandlung von CO/CO2- und H2-Gasgemischen in Kraftstoffe und Zwischenchemikalien ist. In diesem Rahmen befasst sich unsere Gruppe mit verschiedenen Aspekten der Power2X-Strategie, einschließlich Wasserelektrolyse, Methanisierung, FTS, Synthese von Methanol oder höherer Alkohole aus CO/CO2+H2. Die Expertise, die wir in diese globale Herausforderung einbringen möchten, besteht darin, das Katalysatorverhalten unter dynamischen, naturähnlichen Bedingungen mit Hilfe fortschrittlicher Techniken wie In-situ- und Operando-XAS, EXAFS usw. zu bestimmen.

Fortschritte bei der Erzeugung erneuerbarer Wind- und Solarenergie machen diese nachhaltigen Energieformen zu einer praktikablen langfristigen Option, um den steigenden Energiebedarf unserer Gesellschaft zu decken. Es besteht jedoch ein erhebliches Ungleichgewicht zwischen der Stromerzeugung und ihrer Nutzungskapazität. Um diese Probleme zu umgehen, müssen effiziente Energiespeicherlösungen entwickelt werden. Ein Beispiel ist die Power-to-X-Strategie, deren Kern die Umwandlung von CO/CO2- und H2-Gasgemischen in Kraftstoffe und Zwischenchemikalien ist. In diesem Rahmen befasst sich unsere Gruppe mit verschiedenen Aspekten der Power2X-Strategie, einschließlich Wasserelektrolyse, Methanisierung, FTS, Synthese von Methanol oder höherer Alkohole aus CO/CO2+H2. Die Expertise, die wir in diese globale Herausforderung einbringen möchten, besteht darin, das Katalysatorverhalten unter dynamischen, naturähnlichen Bedingungen mit Hilfe fortschrittlicher Techniken wie In-situ- und Operando-XAS, EXAFS usw. zu bestimmen.

Bachelor- und Masterarbeiten verfügbar!

Zugehörige Publikationen

J. Geppert, P. Röse, S. Czioska, D. Escalera-López, A. Boubnov, E. Saraçi, S. Cherevko, J.-D. Grunwaldt, U. Krewer. J. Am. Chem. Soc. 2022, 144, 29.

Pandit, L.; Serrer, M.-A.; Saraҫi E.; Boubnov, A.; Grunwaldt, J.-D. Chem. Methods. 2022, 2, e202100078.

Pandit, L.; Boubnov, A.; Behrendt, G.; Mockenhaupt, B.; Chowdhury, C.; Jelic, J.; Hansen, A.-L.; Saraçi, E.; Ras, E.-J.; Behrens, M.; Studt, F.; Grunwaldt, J.-D. ChemCatChem, 2021, 13, 4120.

Czioska, S.; Boubnov, A.; Escalera-López, D.; Geppert, J.; Zagalskaya, A.; Röse, P.; Saraçi, E.; Alexandrov, V.; Krewer, U.; Cherevko, S.; Grunwaldt, J.-D. ACS catalysis, 2021, 11, 10043.

Escalera-López, D.; Czioska, S.; Geppert, J.; Boubnov, A.; Röse, P.; Saraçi, E.; Krewer, U.; Grunwaldt, J.-D.; Cherevko, S. ACS catalysis, 2021, 11, 9300.

Serrer, M.-A.; Stehle, M.; Schulte, M. L.; Besser, H.; Pfleging, W.; Saraçi, E.; Grunwaldt, J.-D. ChemCatChem, 2021, 13, 3010.

Serrer, M.-A.; Gaur, A.; Jelic, J.; Weber, S.; Fritsch, C.; Clark, A. H.; Saraçi, E.; Studt, F.; Grunwaldt, J.-D. Catal. Sci. Techn. 2020, 10, 7542.

Loewert, M.; Serrer, M.-A.; Carambia, T.; Stehle, M.; Zimina, A.; Kalz, K.; Lichtenberg, H.; Saraçi, E.; Pfeifer, P.; Grunwaldt, J.-D. React. Chem. Eng. 2020, 5, 1071.

M.-A. Serrer, K. F. Kalz, E. Saraҫi, H. Lichtenberg, J.-D. Grunwaldt. ChemCatChem, 2019, 11, 5018.

K. M. Walter, M.-A. Serrer, W. Kleist, J.-D. Grunwaldt. 2019. Appl. Catal. A, 2019, 585, 117150.

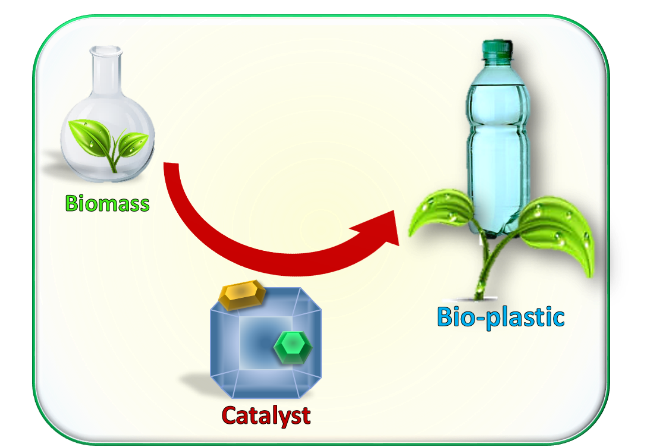

Biomass Conversion

Biomasse ist eine erneuerbare und reichlich vorhandene CO2-neutrale Ressource für die nachhaltige Produktion von Chemikalien, darunter Kraftstoffe, Monomere und andere chemische Bausteine. Unsere Forschung beginnt mit grundlegenden Studien zur Umwandlung von Biomasse-Plattformmolekülen, z.B. Fructose/Glucose, HMF und Fettsäuren sowie katalytische Veredelung von ungereinigten biologisch gewonnenen Lösungen. Wichtige Reaktionen sind Oxidation, Cycloaddition, oxidative Spaltung, Hydrierung usw. Umfassende Studien, einschließlich Katalysatorherstellung, Screening, fortgeschrittener Charakterisierung und Reaktionstechnik, bieten Rationalität beim Katalysatordesign und Prozessoptimierung für eine nachhaltige Zukunft.

Growing Plant Bottles in the Lab - Biobasierte Monomere für „grüne” Flaschen durch innovative Katalyse

Die Synthese von Polymerbausteinen aus Biomasse ist eine attraktive Alternative zur Petrochemie, wenn es um Themen wie Ressourcenverknappung und Nachhaltigkeit geht. Die Verpackungsindustrie, insbesondere die Herstellung von Kunststoffflaschen, hat die höchste Marktnachfrage und ist stark vom Mangel an fossilen Aromastoffen und den Umweltvorschriften betroffen. Daher ist die Synthese von Polyethylenterephthalat (PET) oder Polyethylenfuranoat (PEF), Bausteinen aus nachwachsenden Rohstoffen, ein wichtiges Ziel in Wissenschaft und Industrie. In unserer Gruppe werden verschiedene innovative Wege entwickelt, um diese Monomere effektiv aus Biomasse zu synthetisieren. Katalysatorvorbereitung, Charakterisierung und Reaktionskinetik sind die Werkzeuge, die verwendet werden, um den Prozess zu optimieren und ein umweltfreundliches Produkt zu erhalten.

Die Synthese von Polymerbausteinen aus Biomasse ist eine attraktive Alternative zur Petrochemie, wenn es um Themen wie Ressourcenverknappung und Nachhaltigkeit geht. Die Verpackungsindustrie, insbesondere die Herstellung von Kunststoffflaschen, hat die höchste Marktnachfrage und ist stark vom Mangel an fossilen Aromastoffen und den Umweltvorschriften betroffen. Daher ist die Synthese von Polyethylenterephthalat (PET) oder Polyethylenfuranoat (PEF), Bausteinen aus nachwachsenden Rohstoffen, ein wichtiges Ziel in Wissenschaft und Industrie. In unserer Gruppe werden verschiedene innovative Wege entwickelt, um diese Monomere effektiv aus Biomasse zu synthetisieren. Katalysatorvorbereitung, Charakterisierung und Reaktionskinetik sind die Werkzeuge, die verwendet werden, um den Prozess zu optimieren und ein umweltfreundliches Produkt zu erhalten.

Bachelor- und Masterarbeiten vefügbar!

Zugehörige Publikationen

Neukum, D.; Baumgarten, L.; Wüst, D.; Sarma, B. B.; Saraçi, E.; Kruse, A.; Grunwaldt, J.-D. ChemSusChem. 2022,15, e2022004.

O.R. Schade, F. Stein, S. Reichenberger, A. Gaur, E. Saraci, S. Barcikowski, J.-D. Grunwaldt. Adv. Synth. Catal. 2020, 362, 5681

W. Naim, O.R. Schade, E. Saraci, D. Wüst, A. Kruse, J.-D. Grunwaldt. ACS Sust. Chem. Eng. 2020, 8, 11512

Schade, O. R.; Gaur, A.; Zimina, A.; Saraci, E.; Grunwaldt, J.-D. Catal. Sci. Techn. 2020, 10, 5036.

Schade, O.; Dolcet, P.; Nefedov, A.; Huang, X.; Saraçi, E.; Wöll, C.; Grunwaldt, J.-D.

Catalysts, 2020, 10, 342.

Selektive Oxidationsreaktionen

Selektive Propylenoxidation

Selektive Oxidationsprozesse sind sehr wichtige Reaktionen in der chemischen Industrie für die Produktion einer Vielzahl von Grundchemikalien. Die Oxidation von Propylen zu Acrolein ist eine dieser Reaktionen. Acrolein wird in verschiedenen Prozessen, wie der Produktion von Acrylsäure, einem wichtigem Monomer, weiter umgesetzt. Heutzutage werden multimetallische Oxide auf der Basis von Bismuth und Molybdän in der Oxidation von Propylen verwendet, welche zu hohen Umsätzen und hohen Selektivitäten zu Acrolein führen. Dazu führen wir intensive Forschung über das grundlegende Bismuth-Molybdän-System durch und konnten so Beziehungen zwischen Struktur, Aktivität und Selektivität aufdecken. Dafür wurden verschiedenste Charakterisierungsmethoden, wie Röntgendiffraktometrie (XRD), Röntgenabsorptionsspektroskopie (XAS) und Raman Spektroskopie eingesetzt. Als nächsten Schritt betrachten wir ein Multikomponentensystem, das den real verwendeten Katalysatorsystemen näherkommt, welches aus Bi-Mo-Co-Fe-Oxiden besteht und daher eine Vielzahl verschiedener Phasen aufweist. Alle Schritte der Katalysastorforschung – insbesondere Präparation, Charakterisierung und Tests – werden in unserer Gruppe durchgeführt. Die Präparation erfolgt dabei über Flammensprühpyrolyse und Katalysatortests werden in eigens konstruierten Reaktoraufbauten durchgeführt. Die Charakterisierung erfolgt typischerweise via Raman Spektroskopie, XRD und Physisorption. Ausgewählte Proben werden über in situ/operando Methoden intensiver studiert, um weiteren Einblick in das Katalysatorsystem und tieferes Verständnis zu erhalten. Durch die Kombination von Präparation, Charakterisierung und Tests sind wir in der Lage unsere Katalysatorsysteme rational zu optimieren und zu verbesserten Reaktionsergebnissen zu gelangen.

Selektive Oxidationsprozesse sind sehr wichtige Reaktionen in der chemischen Industrie für die Produktion einer Vielzahl von Grundchemikalien. Die Oxidation von Propylen zu Acrolein ist eine dieser Reaktionen. Acrolein wird in verschiedenen Prozessen, wie der Produktion von Acrylsäure, einem wichtigem Monomer, weiter umgesetzt. Heutzutage werden multimetallische Oxide auf der Basis von Bismuth und Molybdän in der Oxidation von Propylen verwendet, welche zu hohen Umsätzen und hohen Selektivitäten zu Acrolein führen. Dazu führen wir intensive Forschung über das grundlegende Bismuth-Molybdän-System durch und konnten so Beziehungen zwischen Struktur, Aktivität und Selektivität aufdecken. Dafür wurden verschiedenste Charakterisierungsmethoden, wie Röntgendiffraktometrie (XRD), Röntgenabsorptionsspektroskopie (XAS) und Raman Spektroskopie eingesetzt. Als nächsten Schritt betrachten wir ein Multikomponentensystem, das den real verwendeten Katalysatorsystemen näherkommt, welches aus Bi-Mo-Co-Fe-Oxiden besteht und daher eine Vielzahl verschiedener Phasen aufweist. Alle Schritte der Katalysastorforschung – insbesondere Präparation, Charakterisierung und Tests – werden in unserer Gruppe durchgeführt. Die Präparation erfolgt dabei über Flammensprühpyrolyse und Katalysatortests werden in eigens konstruierten Reaktoraufbauten durchgeführt. Die Charakterisierung erfolgt typischerweise via Raman Spektroskopie, XRD und Physisorption. Ausgewählte Proben werden über in situ/operando Methoden intensiver studiert, um weiteren Einblick in das Katalysatorsystem und tieferes Verständnis zu erhalten. Durch die Kombination von Präparation, Charakterisierung und Tests sind wir in der Lage unsere Katalysatorsysteme rational zu optimieren und zu verbesserten Reaktionsergebnissen zu gelangen.

Verwandte Publikationen

P. Sprenger, W. Kleist, J.-D. Grunwaldt, ACS Catal. 2017, 7, 5628-5642.

P. Sprenger, M. Stehle, A. Gaur, A. M. Gänzler, D. Gashnikova, W. Kleist, J.-D. Grunwaldt, ACS Catal. 2018, 8, 6462-6475.

P. Sprenger, T. Sheppard, J.-P. Suuronen, A. Gaur, F. Benzi, J.-D. Grunwaldt, Catalysts 2018, 8, 356.

Grundlegendes Verständnis

In situ / operando Charakterisierung von heterogenen Katalysatoren

Katalysatoren sind allgegenwärtig in der Industrie um Effizienz und Nachhaltigkeit von chemischen Reaktionen zu verbessern. Auf Grund des nicht teilbaren Zusammenspiels von Struktur und Funktion/Aktivität ist es unerlässlich ein tiefes Verständnis und Kontrolle des Zusammenhangs von Struktur und Aktivität über ein Katalysatorsystem zu erhalten. Hochgenaue Daten unter möglichst realisitschen Bedingungen können hierbei bei sogenannten in situ und operando Methoden erhalten werden.

-

In situ bedeutet die Anwendung von analytischen Methoden, wie zum Beispiel Spektrospkopie, Diffraktion oder Mikroskopie unter relevanten Bedingungen für die jeweiligen katalytischen Systeme (z.B.: Eduktzusammensetzung, Temperatur, Druck unter Modell- oder Realbedingungen).

-

Operando bedeutet die simultane Akquirierung von Daten, zeitgleich zu in situ Messungen (was operando-Methoden zu einer speziellen Klasse von in situ-Methonden macht).

Heterogene Katalysatoren sind komplexe Materialien in unterschiedlichsten Formen und Größen. Oft weisen sie interessante strukturelle Elemente und Eigenschaften auf vielen Längenmaßstäben auf. Diese können von aktiven Metallzentren auf atomarer Ebene zu Porositäten (Micro-/Meso-/Makroporen nm bis µm) und Morphologie auf mm- zu cm‑Maßstäben reichen. Multimodale Charakterisierung und Charakterisierung auf unterschiedlichen Maßstäben ist daher essentiell um ein tiefes Verständnis von Katalysatorform und –funktion zu erhalten. Dies beinhaltet unter anderem oberflächenanalytische Methoden wie XPS und DRIFTS (IR) oder auch XRD und Raman. Synchrotronstrahlung spielt hier eine Schlüsselrolle bei Techniken wie Röntgenabsorptionsspektroskopie (XAS), Röntgenemissionsspektroskopie (XES), hochauflösende Synchrotron-Röntgendiffraktometrie (XRD) und Röntgenmikroskopie.

Unsere Gruppe unterteilt in situ und operando-Charakterisierung dabei generell in drei ineinandergreifende Teilgebiete:

- Design und Konstruktion von in situ/operando-Reaktoren und Zellen

- Anwendung der in situ/operando-Spektroskopie, -Diffraktion und –Mikroskopie

- Korrelative Charakterisierung mehrerer komplementärer Techniken (beispielsweise XAS, XRD und Raman oder XAS und DRIFTS).

Ein tiefes Verständnis der katalytischen Aktivität kann nur über Struktur-Aktivität Beziehungen erhalten werden. Dies wiederum führt zu rationalem Katalysatordesign von effektiveren, speziell für bestimmte Reaktionen abgestimmte Katalysatoren. Diese Aktivitätsbeziehungen sind von großem Interesse für die Industrie bei realen Katalysatorsystemen und Bedingungen.

Messungen können am CAT-ACT-Strahlengang am KIT durchgeführt werden.

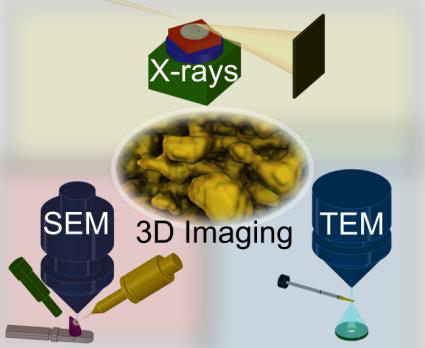

Looking at the Bigger Picture - Kombination von harter Röntgenstrahlung und Elektronenmikroskopie für korrelative Katalysatorbildgebung

Bildgebungstechniken spielen eine fundamentale Rolle in der Katalysatorcharakterisierung. Sie liefern Informationen zur Probenstruktur, -zusammensetzung und –morphologie mit hoher räumlicher Auflösung und bei unterschiedlichen Größenmaßstäben. Transmissionselektronenmikroskopie (TEM) ist optimal für hochauflösende Bildgebung bis auf atomare Größenordnungen, erfordert jedoch strikte Bedingungen bezüglich Gasen und Temperatur. Die Probenauswahl kann auch daher eingeschränkt werden, dass zur Bildgebung nanometerdünne Schichten und die Anwendung von Elektronen hoher Energie nötig sind. Auf der anderen Seite ist Röntgenmikroskopie mit harter Röntgenstrahlung, durchgeführt am Synchrotron, eine flexible Methode, welche auch bei hohen Drücken oder Temperaturen und mit µm-, bis mm-dicken Proben durchgeführt werden kann. Verglichen mit Elektronen ist Röntgenstrahlung weitgehend nicht invasiv, jedoch ist die räumliche Auflösung zurzeit auf den zweistelligen Nanometerbereich limitiert. In der Realität können diese Methoden komplementär eingesetzt werden, indem sie mit passenden Methoden zur Probenumgebung kombiniert werden. XRM und TEM können nicht nur zur Bildgebung, sondern auch für die Aufnahme spektroskopischer und diffraktometrscher Daten zum detaillierteren Verständnis des Analyten eingesetzt werden. Ein wichtiger Punkt ist die Entwicklung von in situ Reaktoren, welche die Bildgebung des Katalysators unter relevanten Bedingungen erlauben - ein optimaler Weg die Struktur-Aktivitäts-Beziehungen des Katalysatorsystems zu betrachten. Die Leistungsfähigkeit dieser Methoden auszunutzen ist ein Schlüsselgebiet unseres Arbeitskreises.

Bildgebungstechniken spielen eine fundamentale Rolle in der Katalysatorcharakterisierung. Sie liefern Informationen zur Probenstruktur, -zusammensetzung und –morphologie mit hoher räumlicher Auflösung und bei unterschiedlichen Größenmaßstäben. Transmissionselektronenmikroskopie (TEM) ist optimal für hochauflösende Bildgebung bis auf atomare Größenordnungen, erfordert jedoch strikte Bedingungen bezüglich Gasen und Temperatur. Die Probenauswahl kann auch daher eingeschränkt werden, dass zur Bildgebung nanometerdünne Schichten und die Anwendung von Elektronen hoher Energie nötig sind. Auf der anderen Seite ist Röntgenmikroskopie mit harter Röntgenstrahlung, durchgeführt am Synchrotron, eine flexible Methode, welche auch bei hohen Drücken oder Temperaturen und mit µm-, bis mm-dicken Proben durchgeführt werden kann. Verglichen mit Elektronen ist Röntgenstrahlung weitgehend nicht invasiv, jedoch ist die räumliche Auflösung zurzeit auf den zweistelligen Nanometerbereich limitiert. In der Realität können diese Methoden komplementär eingesetzt werden, indem sie mit passenden Methoden zur Probenumgebung kombiniert werden. XRM und TEM können nicht nur zur Bildgebung, sondern auch für die Aufnahme spektroskopischer und diffraktometrscher Daten zum detaillierteren Verständnis des Analyten eingesetzt werden. Ein wichtiger Punkt ist die Entwicklung von in situ Reaktoren, welche die Bildgebung des Katalysators unter relevanten Bedingungen erlauben - ein optimaler Weg die Struktur-Aktivitäts-Beziehungen des Katalysatorsystems zu betrachten. Die Leistungsfähigkeit dieser Methoden auszunutzen ist ein Schlüsselgebiet unseres Arbeitskreises.

Zugehörige Publikationen

Y. Fam, T.L. Sheppard, A. Diaz, T. Scherer, M. Holler, W. Wang, D. Wang, P. Brenner, A. Wittstock, J.-D. Grunwaldt, ChemCatChem 2018, 10, 2858

S. Baier, C.D. Damsgaard, M. Klumpp, J. Reinhardt, T. Sheppard, Z. Balogh, T. Kasama, F. Benzi, J.B. Wagner, W. Schwieger, C.G. Schroer, J.-D. Grunwaldt, Microsc. Microanal. 2017, 23, 501.

S. Baier, A. Wittstock, C.D. Damsgaard, A. Diaz, J. Reinhardt, F. Benzi, J. Shi, T. Scherer, D. Wang, C. Kübel, C.G. Schroer, J.-D. Grunwaldt, RSC Adv. 2016, 6, 83031

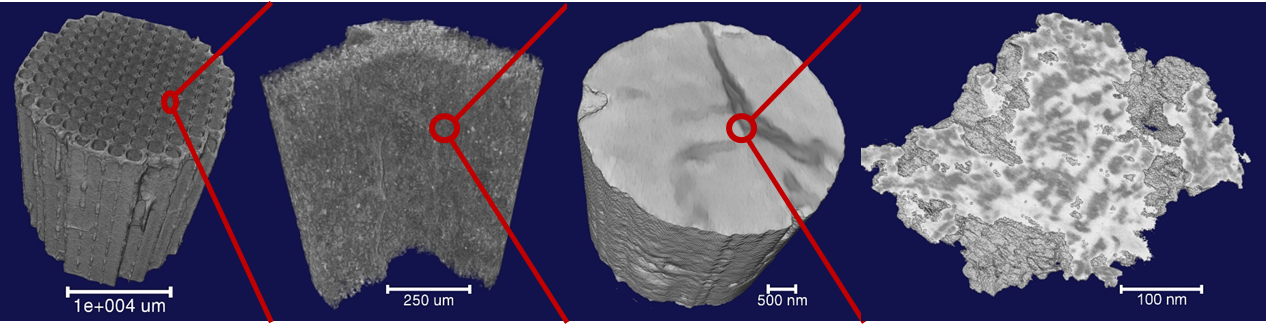

Seeing is Believing - 3D Katalysatorcharakterisierung über Röntgentomographie mit harter Röntgenstrahlung am Synchrotron

Heterogene Katalysatoren sind hierarchisch strukturierte Materialien, welche oft komplexe strukturelle Elemente auf unterschiedlichen Größeneinheiten zeigen. Dies beinhaltet metallische Nanopartikel oder Cluster, Porositäten (inklusive Mikro-, Meso- und Makroporen) und globale Strukturen oder Morphologie, wie beispielsweise Wabenkörper, Presslinge oder Schichten. Detaillierte Charakterisierungen aller Eigenschaften auf allen Größenordnungen ist von großer Bedeutung um ein tiefes Verständnis von Form und Funktion des Katalysators zu erhalten. Harte Röngtenmikro- und –nanotomographie bietet ein vielseitiges Werkzeug um diese Herausforderungen zu meistern. Durch Ausnutzen der Vorteile des hohen Flusses, variabler Energie und sensitivem Detektionsvermögen moderner Synchrotronstrahlung, ist es möglich die 3D-Struktur des Katalysators zu untersuchen. Dies kann mit einer Vielzahl kontrastgebender Methoden, wie Röntgenabsorption (XAS), -fluoreszenz (XRF), -diffraktion (XRD) oder aufkommender, neu entwickelter Methoden wie der Ptychographie, kombiniert werden. Darüber hinaus ermöglicht die Entwicklung neuer Probenumgebung selbst eine in situ 3D-Bildgebung – unter Reaktionsbedingungen. Diese leistungsfähigen Methoden werden in unserer Gruppe ausgenutzt, um das gesamte Katalysatorsystem, von Verteilung und Verhalten der Metallnanopartikel, Abbildung von Porennetzwerken und Überwachung gängiger Deaktivierungsprozesse, wie Sintern oder Verkokung, zu studieren. Die vielen unerforschten Möglichkeiten werden sicherlich zu einer strahlenden Zukunft für die Röntgentomographie in der Katalysatorforschung führen.

Zugehörige Publikationen

P. Sprenger, T.L. Sheppard, J.-P. Suuronen, A. Gaur, F. Benzi, J.-D. Grunwaldt, Catalysts 2018, 8, 356

T.L. Sheppard, S.W.T. Price, F. Benzi, S. Baier, M. Klumpp, R. Dittmeyer, W. Schwieger, J.-D. Grunwaldt, J. Am. Chem. Soc. 2017, 139, 7855

G. Hofmann, A. Rochet, E. Ogel, M. Casapu, S. Ritter, M. Ogurreck, J.-D. Grunwaldt, RSC Adv. 2015, 5, 6893

CATACT-Messlinie an der KIT-Lightsource

CATACT ist Teil der KIT-Lightsource. Dabei handelt es sich um ein Elektronensynchrotron am Karlsruher Institut für Technologie (KIT), das als Synchrotronstrahlungsquelle dient. Die KIT-Lightsource gehört zusammen mit dem KIT zur Helmholtz-Gemeinschaft Deutscher Forschungszentren.

Die CAT-Endstation der CATACT-Beamline an der KIT-Lichtquelle ist der Katalyseforschung mit röntgenspektroskopischen Techniken gewidmet. Sie wird von der Gruppe Grunwaldt am Institut für Katalyseforschung und -technologie (IKFT) und am Institut für Chemische Technologie und Polymerchemie (ITCP) betrieben.

Forschungsinitiativen

Verschiedene Forschungsinitiativen wurden kürzlich über Drittmittel eingeführt. Diese werden hier in Kürze beschrieben (in Arbeit).

|