Modeling of multiphase reacting flows in catalytic systems

Background:

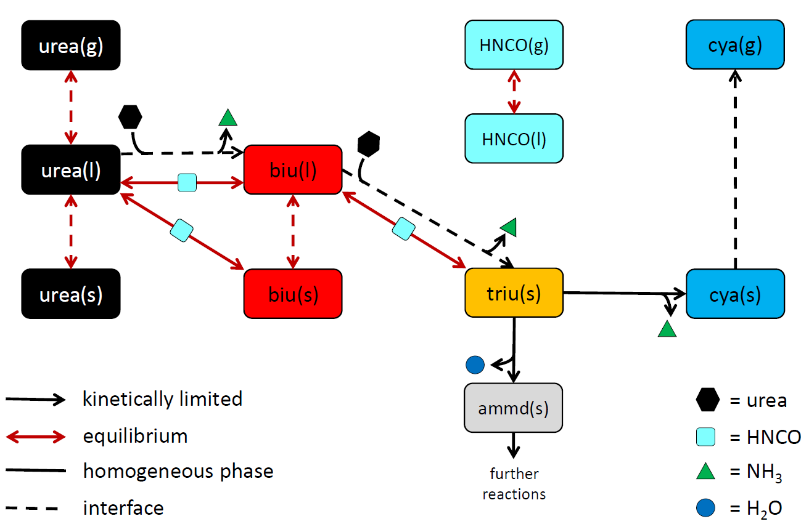

Selective Catalytic Reduction (SCR) of nitrogen oxides (NOx) is based on the selective conversion of NOx to nitrogen (N2) by addition of ammonia (NH3). The injection of AdBlue (32.5 % urea/water solution) in the hot exhaust gas has been developed as feasible alternative. Urea is gradually converted to ammonia by dehydration and subsequent thermolysis and hydrolysis. Due to incomplete evaporation, wall film and solid by-products can be formed as a result of spray-wall interaction, which significantly influence the conversion and the spatial distribution of ammonia over the catalyst cross-section. AdBlue deposits can lead to a failure of the dosing strategy, reduction of the NOx conversion and, in serious cases, to a blockage of the whole SCR-system. Therefore, there is a general need to understand all underlying mechanisms that influence deposit formation from liquid urea.

Project:

Since previous investigations have shown, that the preparation of AdBlue at the beginning of the SCR catalyst is not completed and distances between injection and catalyst inlet are shortened technologically, further investigations will include the whole system up to the end of the catalyst. Goal of the subproject B05 in the SFB TRR 150 is the development of algorithm for the calculation of droplet impingement, evaporation, decomposition products and reaction kinetics on and in the channels of the SCR. Furthermore, an insight in the multiphase flow and its laminarization in the small channels under consideration of the multiphase (gasliquid-solid) reactions should be obtained. This contains the formation of ammonia as well as the homogeneous and heterogeneous catalytically activated gas phase reactions on the SCR catalyst. In detail, models to simulate multiphase flows on catalysts and reaction mechanism of the system exhaust gas/urea/isocyanic acid/hydrolysis/SCR catalyst are developed. Submodels of the chemical processes are then simplified and reduced to integrate them into CFD simulations.

Contact: Christian Kuntz, Dr. Marion Börnhorst, Prof. Dr. Olaf Deutschmann

Funding: