Three-Way-Catalyst under high-frequency lambda switching condition

Background: Compared to conventional internal combustion engines (ICE), hybrid electric vehicles (HEVs) consume up to 49% less fuel under urban driving conditions and can therefore significantly reduce CO2 emissions. However, as a result of frequent engine starts and stops, the exhaust gas temperature is lower for HEVs, which results in a decrease of carbon monoxide (CO), nitrogen oxide (NOx), and unburned hydrocarbons (HC) conversion at the three-way catalyst (TWC) used for exhaust gas aftertreatment. In addition, the unselective reduction of NO in the TWC leads to the formation of the potent greenhouse gas nitrous oxide (N2O) and ammonia (NH3), which is detrimental to both human health and the ecosystem.

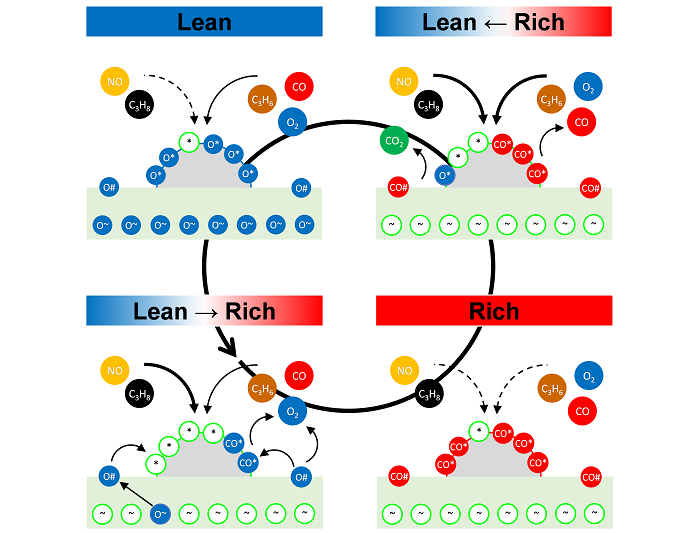

Project: In order to increase the pollutant conversion at the TWC, future ICEs could alternate between a rich and lean mixture instead of controlling the exhaust gas composition stoichiometrically. This method of catalyst operation, so-called dithering, can increase the low-temperature pollutant conversion and thus improve the cold-start performance of the catalyst. The reason for the increase in the reaction rate could not be conclusively clarified in the literature. It is assumed that under steady-state conditions the excess of adsorbed reactants impedes efficient usage of the catalyst surface. The periodic operation removes the strongly adsorbed species from the catalyst on a regular basis, which allows the catalyst to be used more efficiently.

Contact: Daniel Hodonj, Patrick Lott, Olaf Deutschmann

Collaboration:

- Prof. Dr. J. Kusaka (Waseda University, Japan)

- Prof. Dr. T. Koch (Institut für Kolbenmachinen, KIT)

Selected publications:

D. Hodonj, M. Borchers, L. Zeh, G.T. Hoang, S. Tischer, P. Lott, O. Deutschmann, Appl. Catal. B. Environ. 345 (2024) 123657 doi: 10.1016/j.apcatb.2023.123657