|

Ein gut ausgestattetes Equipment auf aktuellem Stand der Technik ist von hoher Bedeutung für unsere Forschung! Daher wird die Ausstattung regelmäßig erweitert oder erneutert. Diese Liste zeigt die neu beschafften Geräte in den letzten Jahren und gibt eine kurze Beschreibung. |

Sample Changer for NMR Spectroscopy [Start of Operation Nov 2023]

Sample changer for Spinsolve 90, Magritek

The Magritek Spinsolve 90 NMR spectrometer (Permanent magnet of 2.1 Tesla) is now equipped with an automatic sample changer. Therefore measurements with a long time scale can be performed much more easily. This is especially useful for the possibility to measure 2D-Spectra, one example are 2D-DOSY spectra, but also many 13C measurements benefit from long measurement time. With this sample changer, these time consuming mesurements can now be performed easily all the day.

NMR Spectroscopy (Medium Field, 90 MHz) [Start of Operation July 2023]

Spinsolve 90, Magritek

The Magritek Spinsolve 90 NMR spectrometer (Permanent magnet of 2.1 Tesla) sets a new standard for NMR instruments. Inspite to the Spinsolve 80 spectrometer, we choose a configuration for 13C and 1H-NMR Spectra. In addition, the machine also allows pulsed gradients (ca 0.5 T/m). In Summary, this machine allows classcial 13C and 1H spectra offering a resolution sufficient for typical polymer spectra and a high sensitivity (SN ca. 240:1, 1%). The pulsed gradient allows additional possibilities: Advanced solvent suppression methods in case you want to combine the NMR with a HPLC separation or offering the possibilities to measure many 2D-Spectra, one example is 2D-DOSY offering the posssibility to measure diffusion coefficients and teh the calculation of molecular weight diistribution without the need of a separation by a colum.

Stress Strain Maschine [Start of Operation July 2021]

Universal tensile testing machine 10kN from Hegewald & Peschke

With this machine, we completed our equipment for mechanical testing of polymeric materials: Capillary rheology for fluids (viscous materials: dynamic viscosity), Tensile Testing for Solids (elastic materials classical E-Modulus) and shear rheology or DMTA for viscoelastic materials determinating the complex E-Modulus.

Suitable for polymer testing:

Oven -70 to 250°C

Long elongation path needed for ductile polymers

Static Testing:

Testing conditions according to DIN

Brittle and ductile materials

Break detection

Dynamic testing:

Arbitary waveform

Dynamic fatigue testing with large deformation amplitudes (>>1cm)

Strain and force controlled

Raw data can be recorded

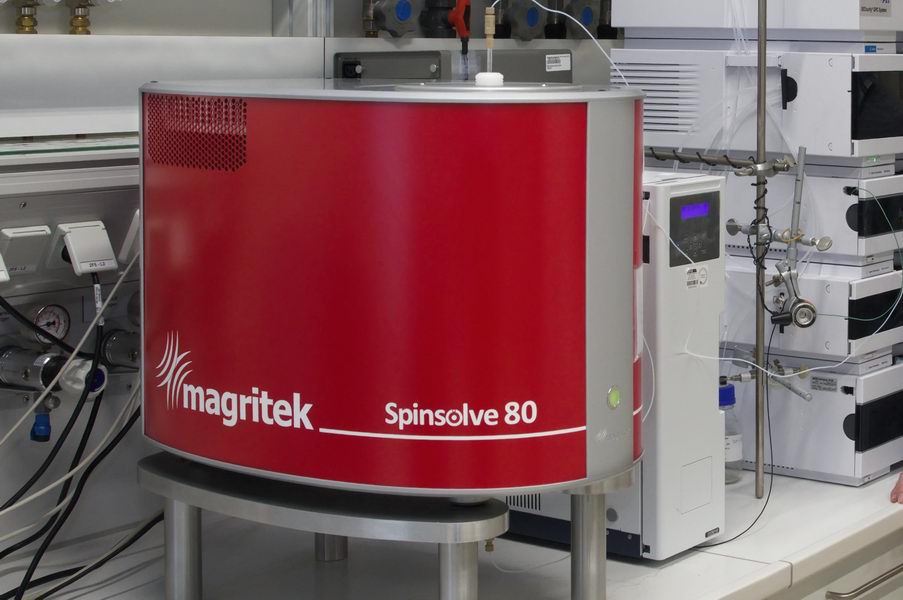

NMR Spectroscopy (Medium Field, 80 MHz) [Start of Operation July 2020]

Spinsolve 80, Magritek

The Magritek Spinsolve 80 NMR spectrometer sets a new standard for NMR instruments. The Spinsolve 80 spectrometer provides high quality 1H NMR spectra in seconds and is based on permanent magnets, therefore no liquid nitrogen or helium is needed for the operation. The Sensitivity is high due to the optimization of all components for only 1H NMR Spectra. The main idea for this spectrometer is the usage in combination with GPC as the Magritec is also able to measure samples in flow. With this combination, we plan to build up a two dimensional charaterisation GPC-NMR, with size resolution due to the GPC and chemical information due to the NMR.

Static and Dynamic Light Scattering [Start of Operation Oct 2019]

The combined instruments for Static- and Dynamic Light Scattering from ALV, Germany offers full flexibility for polymer characterization: Static Scattering for Molecular Weight, Radius of gyration an virail coefficient or the determination of Theta Solvents, Dynamic light scattering for hydrodynamic radius, solvent quality or control of aggregation processes in solution.

The combined instruments for Static- and Dynamic Light Scattering from ALV, Germany offers full flexibility for polymer characterization: Static Scattering for Molecular Weight, Radius of gyration an virail coefficient or the determination of Theta Solvents, Dynamic light scattering for hydrodynamic radius, solvent quality or control of aggregation processes in solution.

The systems is equipped with an extremely strong laser from Cobalt Inc allowing the charaterization from small concentration, the different measurement cells allows volumnia starting from 0.2 ml (only dynamic light scattering), the temperature range is extended up to 90 °C.

High Pressure Batch Foaming System [Start of operation Dez 2018]

Our batch reator is an custum build SFT-High Pressure Reactor from Supercritical Fluid Technologies.

High pressure 100 ml stainless steel vessel with supercritical fluid pump and temperature control unit for batch foaming experiments operating with scCO2 up to 10,000 psi (690 bar) and a max. temperature of 200 °C. Nucleation can be induced either in a one-step foaming process by sudden depressurization or in a two-step foaming process by rapidly heating the saturated sample outside of the reactor in a hot oil bath.

With these system, higher pressure and shorter depressurization times are possible, in addition, the control of the depressuration time is now possible. Therefore, we have more control over the foaming process, and due to the higher pressure one can desolve more blowing gas to achieve foams with lower density and smaller cell size.

The equipment is needed for our research on comb polymers, here we want to study the influence of polymer topology on the resulting foam properties.

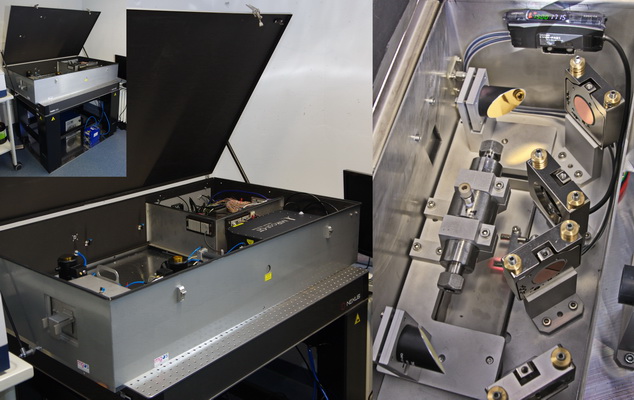

SEC-IR-QCL [start of operation: Jan 2018]

This combination of size exclusion chromatography and IR spectroscopy based on quantum cascade IR lasers (QCL) is a self-construction in cooperation with MG Optical solutions and neoplas GmbH.

This combination of size exclusion chromatography and IR spectroscopy based on quantum cascade IR lasers (QCL) is a self-construction in cooperation with MG Optical solutions and neoplas GmbH.

The systems allows correlated information about molecular size and special chemical groups detected via IR. Due to the high intensity of the QCL-lasers, rare groups are accessible not detecblabe in FTIR-Spectroscopy.

Application example: Amount of rare functional groups (at the moment: 1 Carbonyl group in a polymer of 500.000 g/mol), in future also planned for determination of endgroups and branching units.

One part of the self-developed 3-dimensional spectroscopy: dim1:Size via SEC, dim2: chemical composition via SEC-FTIR or SEC-NMR, dim3: topology, endgroups via SEC-IR-QCL

TA-Instruments ARES G2 (2nd instrument in the group) [start of operation Sept 2017]

Rheology is one of the basics methods for the research fields of our group. This second modell of the HighEnd-Rheometer of the latest generation offers new measurement capacities that are needed in our group due to the expansion of the group and due to the new combination Rheo-NMR requiring long measurement times.

Rheology is one of the basics methods for the research fields of our group. This second modell of the HighEnd-Rheometer of the latest generation offers new measurement capacities that are needed in our group due to the expansion of the group and due to the new combination Rheo-NMR requiring long measurement times.

The Complete System is from TA-Instruments, with sample geometries for liquids and melts, oven with digital monitoring of sample, temperature range between -70 °C and 400 °C. The sensitivity of the new rheometer covers an extremely high range starting from 0.05 µN/m to 200 mN/m offering a factor of 8 for low torque measurements and a factor of 2 for high torques compared to the old ARES. Therefore, it offers the possibility to measure low-viscosity liquids as water as well as special polymers with high stiffness.

SEC-NMR (SEC from PSS, NMR: Magritek Spinsolve 60 start of operation July 2017]

This characterization method allows to analyze blends or copolymers not only for their average composition. It delivers the full composition as a function of the size of the molecule. For further information please see the page in the research areas "Low-field-NMR and SEC"

Keyence Digital microscope VHX 900F [start of operation June 2017]

The microscope will be used in projects like foaming of model polymers or nanoparticle-hydrogels where the optical impression is needed to judge the success of a synthetic approach.

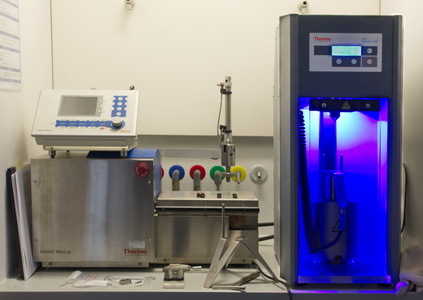

Haake Minijet Pro [start of operation march 2017]

The Haake Minijet Pro is a injection molding machine for lab scale, starting from sample amounts as low as 2 ml. Our system is equipped with several geometries, including specimens according DIN regulations and simple platets for rheological experiments. In combination with the Haake MiniLab, an extruder in lab scale (see left side of picture), we can produce also composites or blends.

The Haake Minijet Pro is a injection molding machine for lab scale, starting from sample amounts as low as 2 ml. Our system is equipped with several geometries, including specimens according DIN regulations and simple platets for rheological experiments. In combination with the Haake MiniLab, an extruder in lab scale (see left side of picture), we can produce also composites or blends.

Therefore, this new equipment offers the possibility for test specimens even for small amounts available, e.g. for our self-synthesized model polymers.

Capillary rheometer Göttfert Rheograph 50 [start of operation oct 2016]

This new capillary rheometer is a big improvement compared to the existing older model from the same company.

With this system, one can examine extremely high shear rates up to 6 Mill s^-1. This is enough to simulate conditions in polymer processing as well as for lubricants in mechanic engines.

In addition, this rheometer can cool and heat, so one can measure food, e.g. chocolate at realistic conditions.

Also PVT-Measurements can be performed. The relation between pressure, volume and temperature is an established method for measuring material compressibility under processing conditions, an information necessary for the optimization of cylce times in polymer processing, especially in injection moulding.

al tensile testing machine 10kN from Hegewald & Peschke

al tensile testing machine 10kN from Hegewald & Peschke Suitable for polymer testing:

Suitable for polymer testing: Our batch reator is an custum build SFT-High Pressure Reactor from Supercritical Fluid Technologies.

Our batch reator is an custum build SFT-High Pressure Reactor from Supercritical Fluid Technologies.