| Ausstattungsliste gegliedert nach verschiedenen Bereichen (Gerätekurzbeschreibungen in Englisch) (hier Link zur kompletten Liste aller Geräte) |

Polymer Extrusion (Laboratory Scale)

Polymer Extrusion (Laboratory Scale)

Labstation, Brabender

Contact Person: Ingo Naue

Brabender extruder (Single screw, properties: D=19mm, L=250mm, Tmax=400°C)

used for examination of melt instabilities during extrusion.

Polymer Extrusion (Model Samples)

Polymer Extrusion (Model Samples)

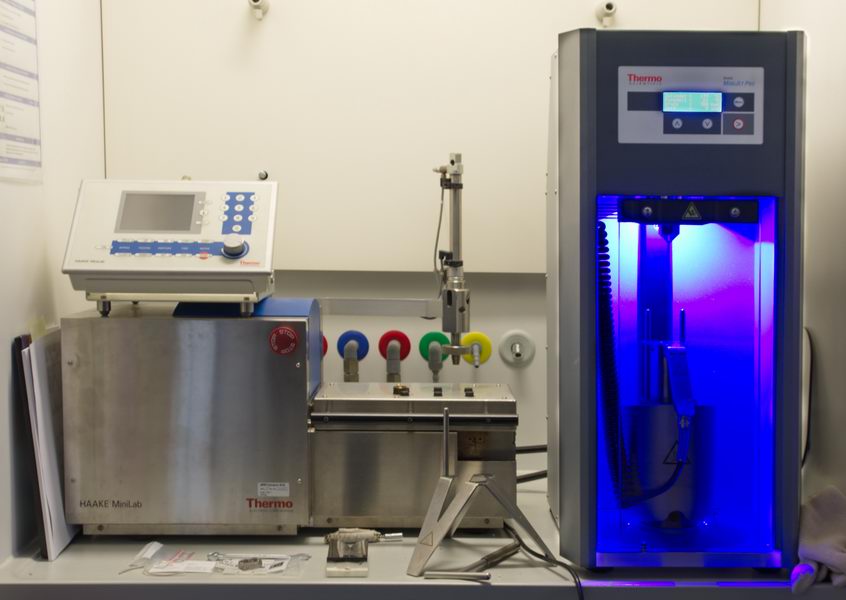

Haake Minilab, Thermo Scientific

Contact Person: Zimmermann Daniel

Haake Minilab: Mini Extruder for sample amount as small as 5 g. Equipped with double screws for better mixing, used for model compound or composite materials out of self synthesized materials due to the limited batch size in laboratory.

Injection Molding

Injection Molding

Haake MiniJet Pro, Thermo Scientific

Contact Person: Zimmermann, Daniel

Haake Minijet Pro: injection molding machine for lab scale, starting from sample amounts as low as 2 ml. In combination with the Haake MiniLab, an extruder in lab scale (see left side of picture), we can produce also composites or blends.

we have a large number of sample geometries at our disposal: Bones for tensile testing in different sizes, round discs for shear rheology and rectangular plates for DMTA measurements.

Polymer Foaming (Batch reactor)

Polymer Foaming

Custum build SFT-High Pressure Reactor from Supercritical Fluid Technologies

Contact person:

High pressure 100 ml stainless steel vessel with supercritical fluid pump and temperature control unit for batch foaming experiments operating with scCO2 up to 10,000 psi (690 bar) and a max. temperature of 200 °C. Nucleation can be induced either in a one-step foaming process by sudden depressurization or in a two-step foaming process by rapidly heating the saturated sample outside of the reactor in a hot oil bath.

The equipment is needed for our research on comb polymers, here we want to study the influence of polymer topology on the resulting foam properties.