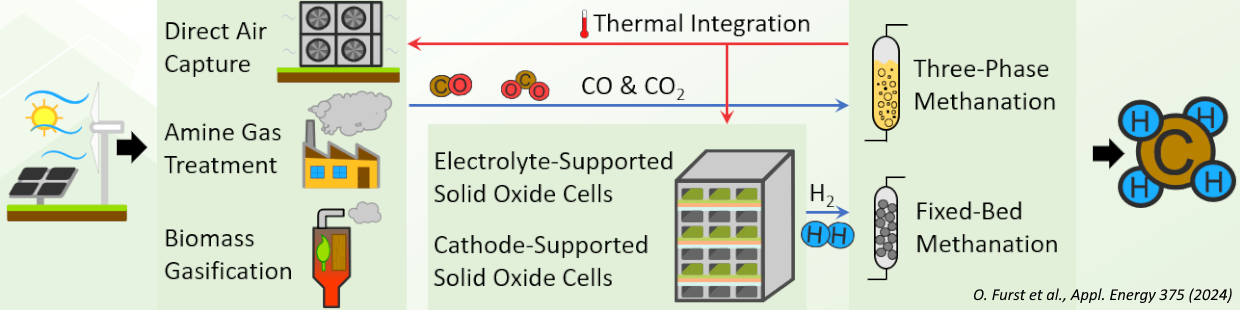

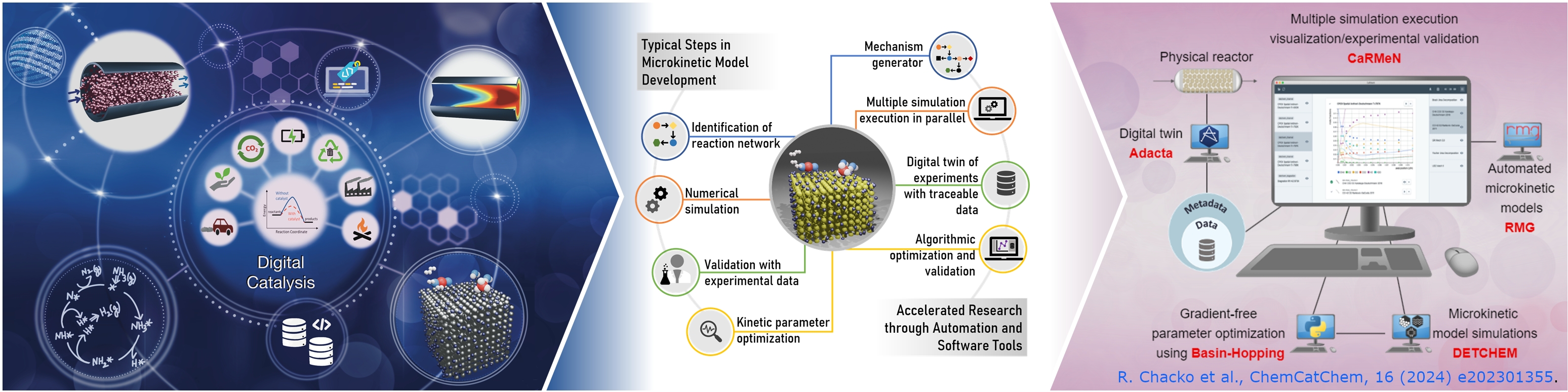

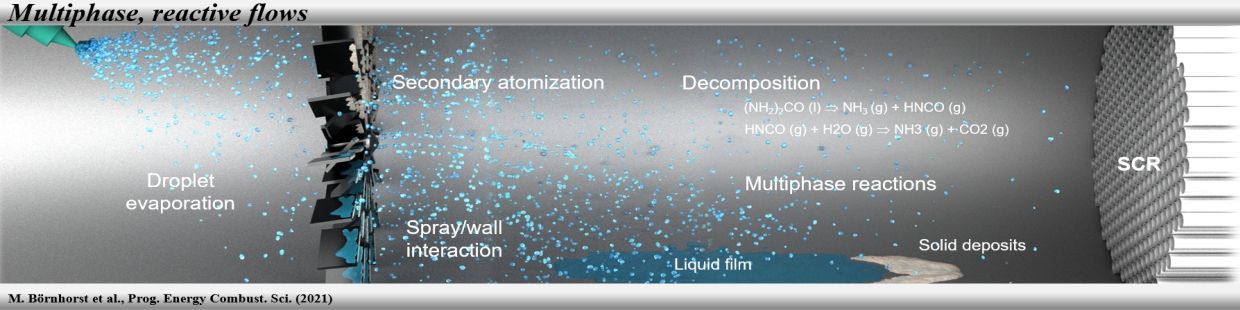

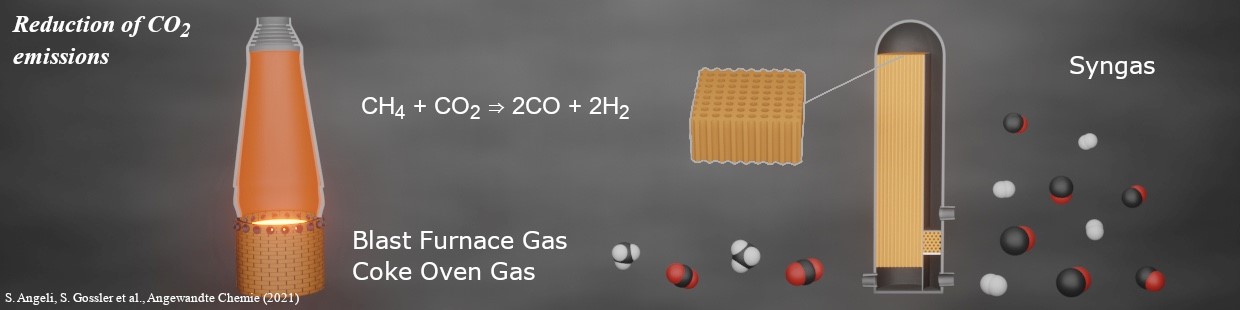

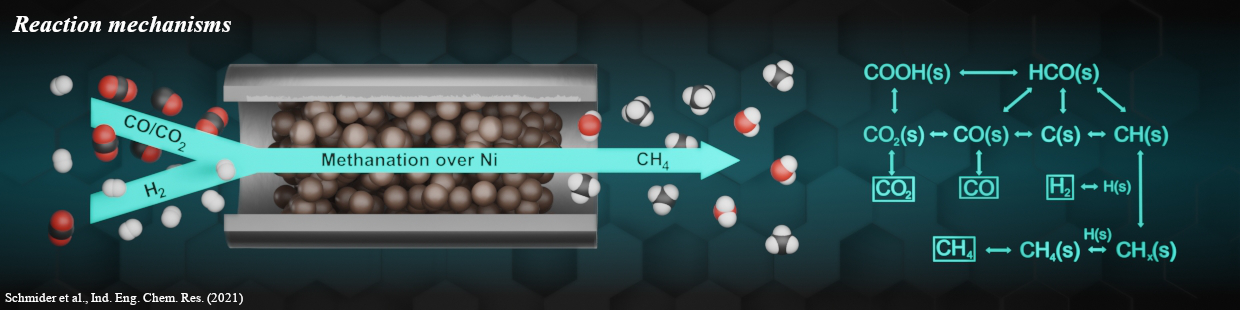

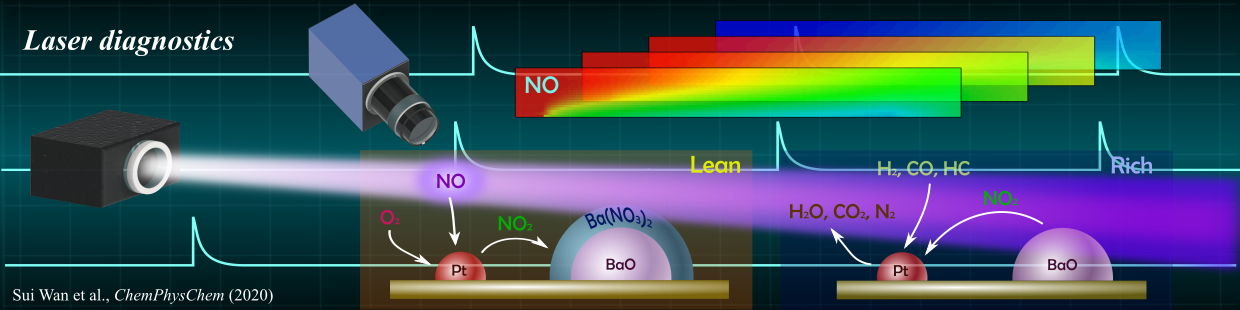

We work on environmental and climate friendly novel chemical technologies. Our current research projects focus on the reduction of emissions of greenhouse gases (CO2, CH4, N2O) and local pollutants (NOx, particulate matter etc.) from processes in chemical industry, traffic, transportation, and the energy sector. Aside from developing advanced experimental tools for a better understanding of chemical reactors, we give a special emphasis on mathematical modeling and numerical simulation of technical processes.

The Deutschmann research group is part of the Institute for Chemical Technology and Polymer Chemistry (ITCP) and belongs to both the Faculty of Chemistry and Biosciences and the Faculty of Chemical and Process Engineering within Division I at KIT.

In catalysis research, we are closely linked to the IKFT and the Grunwaldt group. Our joint work on emission control is part of the Exhaust Gas Center Karlsruhe and the CRC 1441 TrackAct. In the ENERMAT laboratory, we study fuel and electrolysis cells. Within the CRC/TRR150 and Clean Circles, we collaborate with TU Darmstadt on reactive flowsand carbon-free chemical energy carriers, respectively.

Patrick Lott, group leader at ITCP and CTO of the Center for Emission Control Karlsruhe, received the Best Presentation Award from the American Society of Mechanical Engineers (ASME), ICE Division, for his talk titled “Spatiotemporal Insights During Forced Dynamic Reactor Operation for Fast Light-Off and Enhanced Low-Temperature Methane Oxidation over Pd-Based Catalysts.” The award was presented during this year’s ICE Forward Conference, held in Milwaukee, WI, USA, from October 19–21. Congratulations to Patrick on this achievement! 27.10.2025

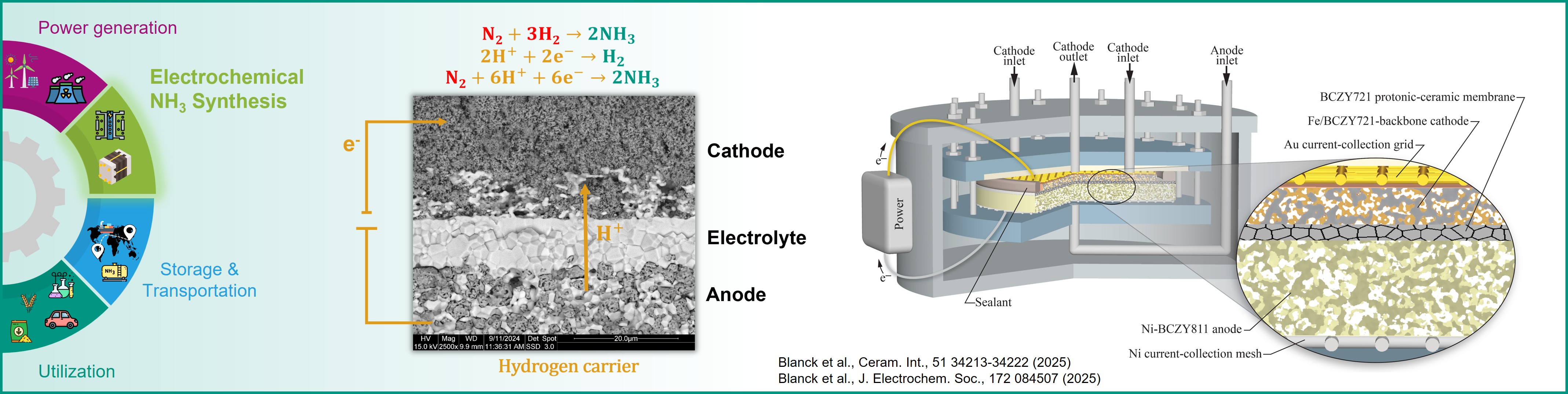

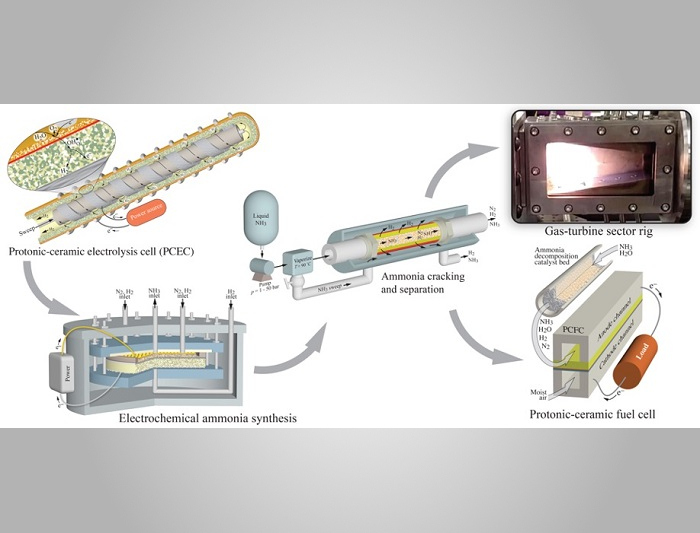

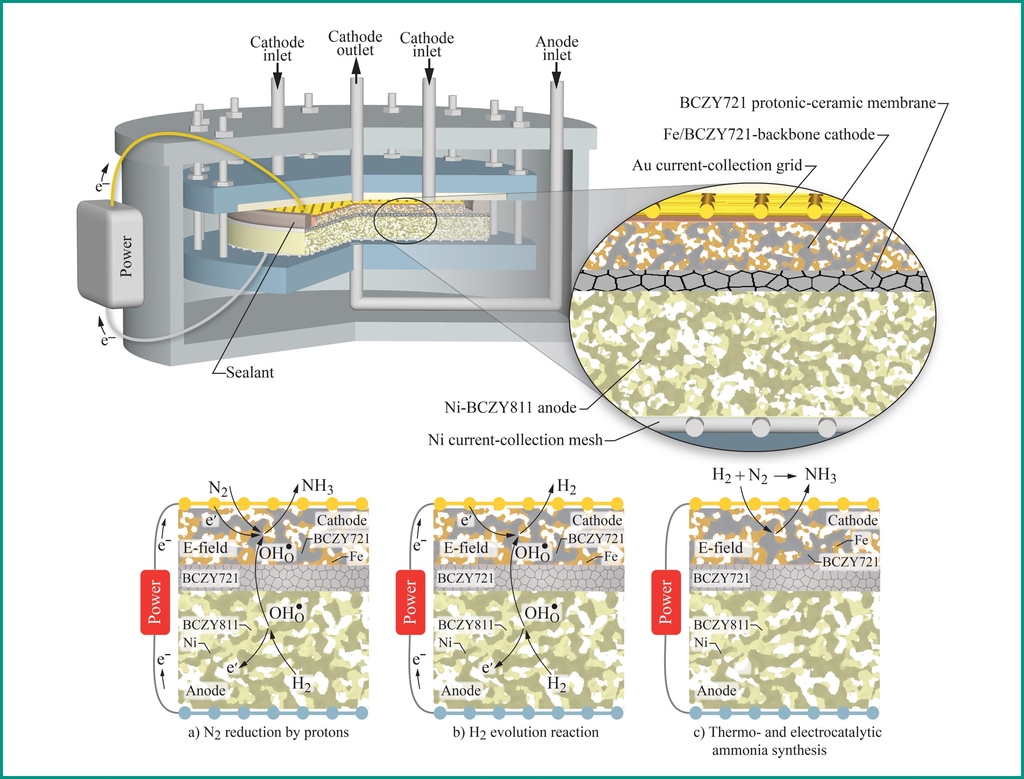

Based on the very fruitful collaboration of EIFER, Colorado School of Mines, and our group on electrochemical synthesis of ammonia, funded by NSF and DFG, leading to the impressive results of Blanck et al., a plenary lecture at the 4th NH3 Symposium in Minneapolis was given by R.J. Kee and O. Deutschmann. 09.10.2025

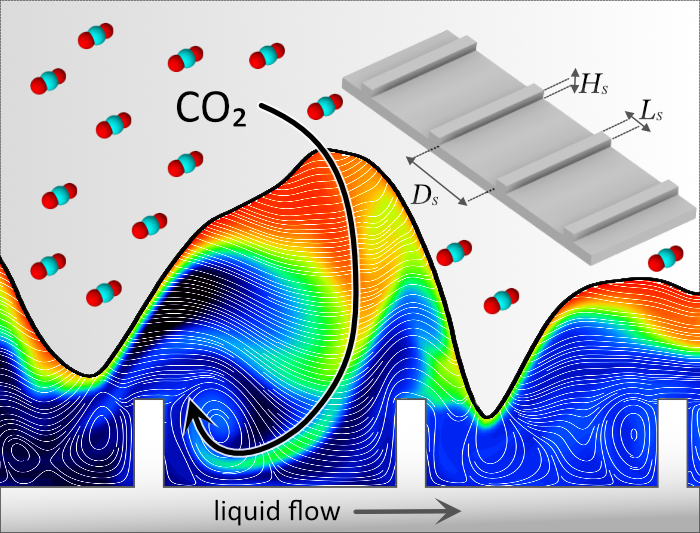

A new study published in the Chemical Engineering Journal reveals how structured surfaces can dramatically enhance CO₂ absorption in falling film absorbers. Researchers from Karlsruhe Institute of Technology and TU Dortmund found that surface-induced resonance waves intensify mass transfer by disrupting the liquid film’s flow. Compared to smooth surfaces, tailored structures increased the volumetric mass transfer coefficient by up to 4.1 times. Using a combination of experiments and simulations, the team showed that structure induced internal convective mixing is key to this improvement. These findings could significantly reduce energy costs in carbon capture processes. 14.10.2025

Our team has published new studies reporting major advances in electrochemical ammonia synthesis with proton-conducting ceramic cells. A novel iron-based electrode architecture demonstrates outstanding mechanical stability and chemical robustness, overcoming the limitations of conventional designs while maintaining high catalytic performance. Complementary investigations provide detailed mechanistic insights, revealing the minor role of proton transport, the critical influence of voltage, and the decisive impact of thermodynamic constraints on ammonia formation. Together, these results establish important benchmarks for electrode engineering and process optimization, opening new pathways toward sustainable ammonia production. 08.10.2025

Wir am Institut für Technische Chemie und Polymerchemie trauern um unsere langjährige Kollegin Andrea Rösel, die am 8. Juni 2025 im Alter von 62 Jahren nach kurzer, schwerer Krankheit verstorben ist. Frau Rösel war sehr verantwortungsvoll viele Jahre in verschiedenen Funktionen am Institut tätig und kümmerte sich bei uns mit viel Erfahrung und Engagement, immer mit einem freundlichen Lächeln und einem offenen Ohr, um den SFB 551 sowie die Verwaltung und das Sekretariat. Nun müssen wir Abschied nehmen. Unser Mitgefühl gilt ihrer Familie und ihren Freunden. Wir werden Andrea Rösel stets in liebevoller Erinnerung behalten. 07.07.2025

Olaf Deutschmann's and Patrick Lott's presentation "Dynamics in environmental catalysis: from surface coverages to reactor operations" was given as one of the invited plenary talks at this year's International Conference on Environmental Catalysis. ICEC 2025 took place in Isola delle Femmine (PA - Sicily, Italy), 2-5 June 2025. More about ICEC 2025 here. 03.06.2025

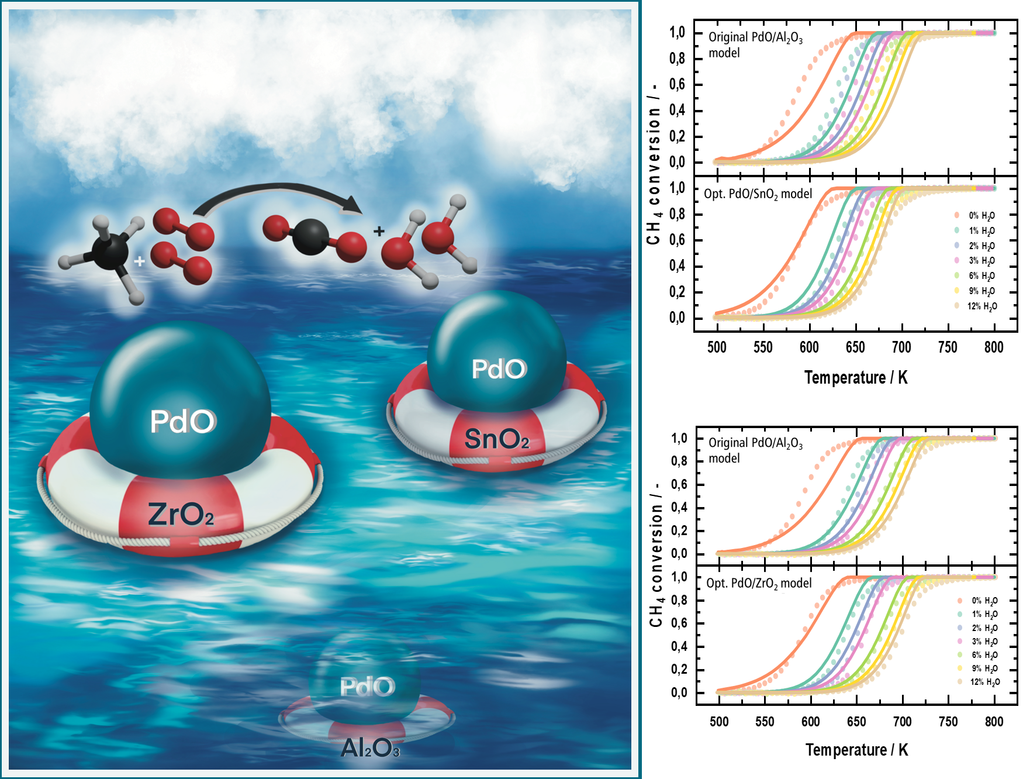

In a recently published article in ACS Catalysis, we present two new sets of kinetic parameters that accurately simulate the water inhibition effect during methane oxidation on PdO catalysts supported over SnO2 and ZrO2. These parameters were optimized using an automated optimization routine in conjunction with the DETCHEMPBR simulation code. The study provides a detailed analysis of the reaction mechanism, highlighting the influence of the support materials on the reaction pathways at the PdO surface. 08.05.2025

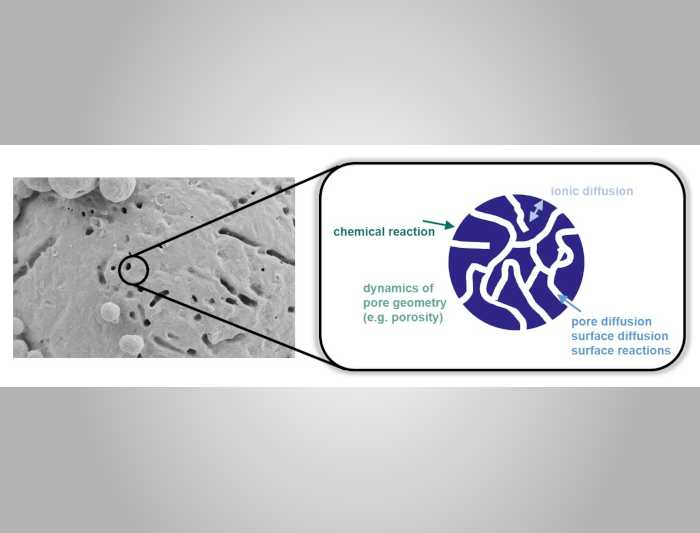

In a collaborative, DFG-funded (ID 558715615) project with the Institute of Mechanical Process Engineering and Mechanics and the Engler-Bunte-Institute our team is exploring iron powder as a carbon-free chemical energy carrier. The project aims to deepen the understanding of the reduction of iron oxide particles with hydrogen - a key step in the storage cycle. By combining experimental studies, detailed particle characterization, and advanced modeling and simulation, the project seeks to uncover the complex reaction mechanisms and transport processes involved. The insights gained will lay the groundwork for optimizing the redox cyclability of iron particles and advancing their use in sustainable energy storage. 14.04.2025

The paper for our newly developed application, CaRIn (Catalysis Research with Infrared Spectroscopy), introduces a tool for real-time adjustment of peak broadening in simulated infrared spectra using Gaussian functions. Integrated within the CaRMeN platform, it enhances the comparability of experimental and theoretical spectra while streamlining workflows with a built-in spectral database. This innovation improves the accuracy and usability of computational spectroscopy in catalysis research. 20.03.2025

Prof. Dr. Olaf Deutschmann

ITCP

Email: deutschmann ∂does-not-exist.kit edu

Secretary:

Tel. +49 721 608 43064

Fax +49 721 608 44805