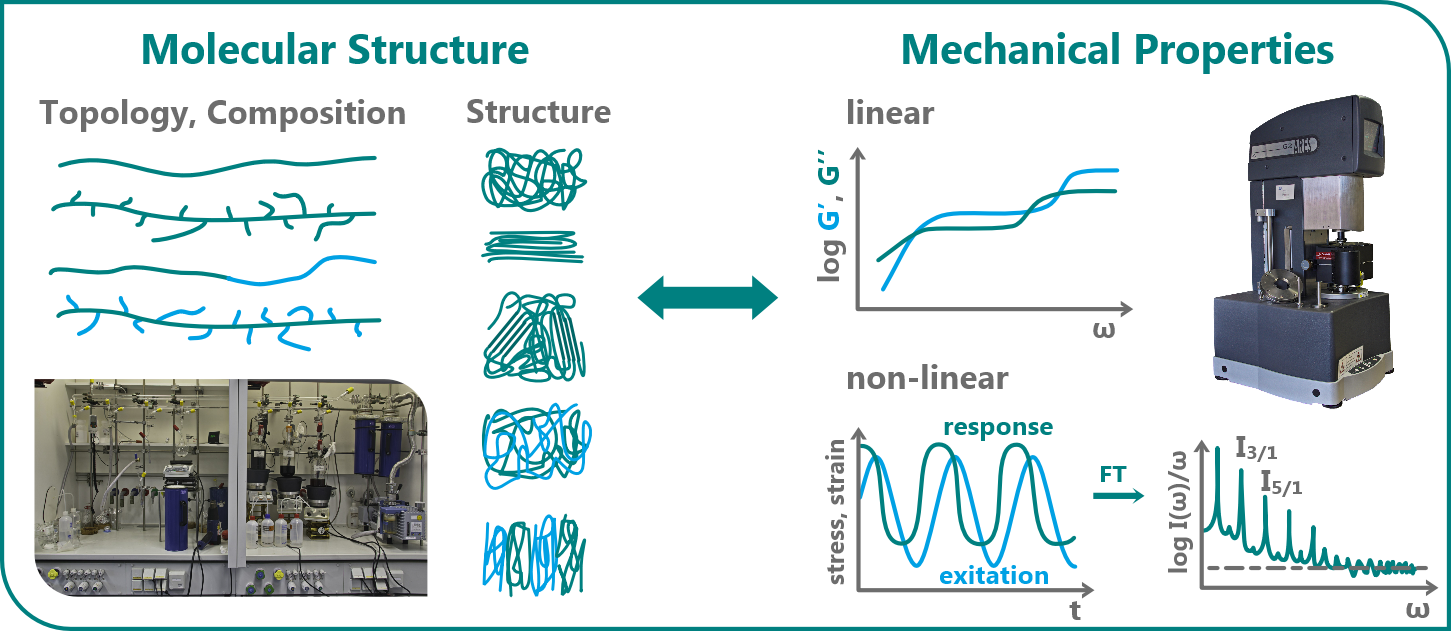

Mechanical and rheological properties are commonly used to set processing conditions or design polymer applications. These material properties originate in the molecular structure of the polymer. Neither this structure, nor its connection to the resulting material properties is usually known in detail. Therefore, the correlation between mechanical properties and the molecular structure is a major issue in our research (fig.1)

|

Fig.1: Interaction of research strand synthesis with research strand rheology. |

| Fourier Transformation Rheology (FT-Rheology), extends the standard method of oscillating rheology into the non-linear regime and was developed in our group. Recently, we introduced a new non-linearity parameter Q. Examples of its use can be found in literature [Cziep et al., 2016]. The parameter Q is extremely sensitive to the topology of polymers, one can distinguish e.g. linear and star polymers. It also reflects strongly the influence of long-chain branching even for extremely low concentrations of branching points. This is an important ability because the influence of long-chain branches on the processing properties are drastically, but the detection and quantification is complicated via alternative methods. Also other material classes’ benefits from our developments in non-linear rheology, e.g. filled rubbers and emulsions. |

Another topic are Flow instabilities in polymer melts and the method of capillary rheology: We developed new dies for capillary rheology that can measure pressure fluctuation inside the die allowing to determine the onset of flow instabilities an important problem in production limiting the throughput in industrial production. Actual research here are dies that can measure normal forces, this will help to understand flow instabilities better.

| FT-Rheology (more Info available) |

|---|

| Flow instabilities of polymers |

|---|

| Pressure fluctuations in dies in capillary rheology or in extrusion |

|---|

| Normal forces in capillary rheology |

|---|

| Please see also the full list of publications | |

|---|---|

| An Intriguing Array of Extrudate Patterns in Long‐Chain Branched Polymers During Extrusion | S. Pashazadeh; A. Aulova; C. K. Georgantopoulos; M. Bek; I. Vittorias; I. F. Naue; M. Wilhelm; R. Kádár; Macromol Mater Eng 308 (2023); DOI 10.1002/mame.202300088 |

| Role of molecular architecture and temperature on extrusion melt flow instabilities of two industrial LLDPE and LDPE polyethylenes investigated by capillary rheology, high‐pressure sensitivity slit die and optical analysis | C. K. Georgantopoulos; M. K. Esfahani; I. F. C. Naue; M. Wilhelm; R. Kádár; J Appl Polym Sci 140; e53165 (2023); DOI 10.1002/app.53165 |

| A new slit‐radial die for simultaneously measuring steady state shear viscosity and first normal stress difference of viscoelastic liquids via capillary rheometry | M. Khabazian Esfahani; C. K. Georgantopoulos; I. F. C. Naue; J. Sunder; M. Wilhelm; J Appl Polym Sci 139; p 52094 (2022); DOI 10.1002/app.52094 |

| Modeling the spatial characteristics of extrusion flow instabilities for styrene-butadiene rubbers. Investigating the influence of molecular weight distribution, molecular architecture, and temperature | C. K. Georgantopoulos; M. K. Esfahani; C. Botha; M. A. Pollard; I. F. C. Naue; A. Causa; R. Kádár; M. Wilhelm; Phys Fluids 33; p 93108 (2021); DOI 10.1063/5.0061334 |

| Fatigue life prediction via the time-dependent evolution of linear and nonlinear mechanical parameters determined via Fourier transform of the stress | V. Hirschberg; M. Wilhelm; D. Rodrigue; Journal of Applied Polymer Science 135, 46634 (2018); DOI 10.1002/app.46634 |

| High sensitivity measurements of normal force under large amplitude oscillatory shear | I. F. C. Naue; R. Kádár; M. Wilhelm; Rheologica Acta 57, 757–770 (2018); DOI 10.1007/s00397-018-1111-y |

| First normal stress difference and in-situ spectral dynamics in a high sensitivity extrusion die for capillary rheometry via the ’hole effect’ | R. Kádár, I.F.C. Naue, M. Wilhelm; Polymer 104, 193-203 (2016); DOI 10.1016/j.polymer.2016.07.061 |

| Fourier–Transform rheology of unvulcanized, carbon black filled styrene butadiene rubber | L. Schwab, N. Hojdis, J. Lacayo-Pineda, M. Wilhelm; Macromol. Mat. Eng. 301 457-468 (2016); DOI: 10.1002/mame.201500356 |

| A New High Sensitivity System to Detect Instabilities During the Extrusion of Polymer Melts | I.F.C. Naue, R. Kádár, M. Wilhelm; Macromol. Mater. Eng. 300 1141–1152 (2015); DOI: 10.1002/mame.201500148 |

| Correlation between polyethylene topology and melt flow instabilities by determining in-situ pressure fluctuations and applying advanced data analysis | H. Palza, S. Filipe, I.F.C. Naue, M. Wilhelm; Polymer 51 522-534 (2010); DOI 10.1016/j.polymer.2009.11.050 |